On Beef Tenderloin, Wet Ageing, & Dry Ageing

In my previous post on dry ageing beef (DA), I described how prior to refrigeration, meat was aged by hanging to promote tenderness and enhance flavour. Tenderization comes about from enzymes naturally present in meat which break down tough muscle and connective tissues through the process of proteolysis. Flavour change is more complex, but in part results from oxidation of fats, enzymatic activity, and depending on who you believe, microbial activity. Unfortunately hanging meat in the open air meant temperature and humidity could not be controlled and left the meat vulnerable to spoilage from harmful bacteria. However, with the development of refrigeration, it was possible to DA safely and reliably.

But even with refrigeration, it wasn’t until the 1950’s that DA beef became popular; that’s when the meat and restaurant industry recognized they could market and charge extra for the improved tenderization and flavour DA provided. The downside was that DA was more costly because as the meat aged and “dried out”, it lost weight. As well it was time consuming taking a minimum of 21 days for tenderization and even longer, at least 28 days, for any appreciable changes in flavour.

At about the same time, so called wet aging (WA) was adopted. With WA, meat is vacuum packed in a plastic bag and allowed to “age”. In this way, the meat becomes more tender, but as it is sealed in a bag, it doesn’t lose water preserving weight and therefore profit.

It is interesting that WA beef was possible before the start of World War II, even before DA became common place in the 1950’s, but WA wasn’t widely adapted until later in the 1960’s. As documented on the Sealed Air website, the French inventor Henry DePoix coined and created the CRYOVAC® brand process to better preserve meat for French soldiers stationed along the German-French border. In 1938 he introduced his process to the American businessman Bradley Dewey Sr., cofounder of Dewey & Almy Chemical Company.

For a variety of reasons though, through the war and into the 1950s, the company struggled to get the food industry to adopt shrink-wrapped food packaging. Eventually with investment capital, development of a durable, flexible, graphic-ready plastic material, machines to automate the CRYOVAC process, and aggressive marketing, the CROVAC process took off in the 1960’s. Now, WA is the dominant method of aging beef.

As noted, enhanced tenderness only takes a few days while the flavour enhancement at least 28 days. So if moisture loss is the main reason all beef isn’t DA and WA preserves moisture, why not just WA for longer? In part because of the risk of introducing anaerobic bacteria which would thrive in the vacuum sealed environment and spoil the meat. And if you are of the school that certain moulds contribute to the flavour of DA beef, while anaerobic bacteria can grow in these conditions, mould can not. Lastly, sealed in plastic, the meat “ages” in its own juices (that’s why it’s called “wet ageing”). Because this serum and meat juice can’t drain away or evaporate as occurs in DA, WA meat can have what many describe as a "sour" or "serum-y" flavour. Besides, it turns out in a study conducted by the Nebraska Beef Council in conjunction with the University of Nebraska, most consumers are more interested in the tenderness of their steak that both WA and DA promotes, and less in the flavour DA imparts or even the amount of marbling. Further, not everyone likes the “funky” blue cheese nutty flavours DA meat develops.

Remember that in DA, surface fat is good as it helps protect meat from drying out and contributes to flavour changes in part from oxidation of fats. (Additional flavour enhancement come from enzymatic activity, and depending on who you believe, microbial activity.) WA therefore is particularly suited for leaner cuts of meat with out much fat or marbling including

Flat-Iron Steak

Filet Mignon

Boneless Strip Steak

Flank Steak

It begs the question though, does DA provide any benefit to these leaner cuts of meat and in particular filet mignon. My butcher didn’t think so and thought I was just wasting my money as filet mignon / tenderloin is 1) already extremely tender (it comes from a non weight bearing muscle and therefore has little collagen which makes weight bearing meat tough), 2) has little external fat or mass to protect it from excessive drying out, and 3) little marbling to contribute to enhanced flavour.

Despite being one of the most tender cuts of meat, tenderloin is also relatively bland tasting given it has so little marbling. If one could mitigate the water and trim loss, then maybe the flavour changes imparted by DA would be worth it. As this seemed to be the experience of members of the the The Official Steakager Owner’s Facebook group I set out to DA a tenderloin.

To limit water and trim loss, its best to have a big piece of meat with relatively little surface area, and what surface area there is would have been trimmed away anyway. So rather than getting a prepared tenderloin, I sourced an untrimmed piece with the silver skin, chain, and side muscle attached (known as PSMO; peeled side muscle on).

PSMO vacuumed sealed in Cryovac. Note the juices in the bag on the right which had I kept unopened would yield a WA piece of meat.

You can just make out the chain running along the length at the bottom of the tenderloin, the thin triangular flattish tail on the right, and the heal (also called the wing) at the other end.

Normally one would trim a wet aged PSMO as above.

I only removed the tail piece which being so thin would dry out into a piece of leather. In addition I cut off a a bit of the smaller diameter tenderloin at the end with its attached chain so as to create in the remaining tenderloin, a piece of meat with a uniform diameter. Note the fat and silverskin were left to protect the underlying meat from drying out. Only after DA was the tenderloin further broken down.

The trimmed bits yielded some chain meat, the tail, and two small tenderloin steaks. (See below)

Typically in WA tenderloin, the meat trimmed from the thin end is often used for small tournedos or medallion steaks, as well as quick-cooking dishes like Beef Stroganoff. The chain is most often used for ground meat, but depending on the amount of fat and tenderness, it makes excellent beef skewers, stir-fry, and stews.

To create an even cylindrical shape, I used some butcher’s twine. This then went in to my dedicated drying fridge, a PRO 40 from Steakager for 15 days. Not too long so as to preserve meat yield, but long enough to both enhance tenderness and to a lesser extent flavour of an otherwise bland tasting cut of meat.

Filet tied off to create a reasonably uniform diameter so meat would hold its shape an DA evenly.

Filet attached to rack before placing in SteakAger.

Tenderloin in fridge. Day one of fifteen!

After 15 days, the tenderloin was pulled from the fridge and the chain, heal, and pellicle removed yielding a glorious trimmed tenderloin. I elected to cut it into individual filet mignon steaks, but next time I will keep the centre cut / chateubriand intact for a beef wellington!

After 15 days, meat was pulled.

Notice the outer dried pellicle which needs to be trimmed.

Butcher’s twine removed.

The dried pellicle and chain removed. This wasn’t wasted though and was used as part of a ground meat mix to which it added complexity and DA flavour.

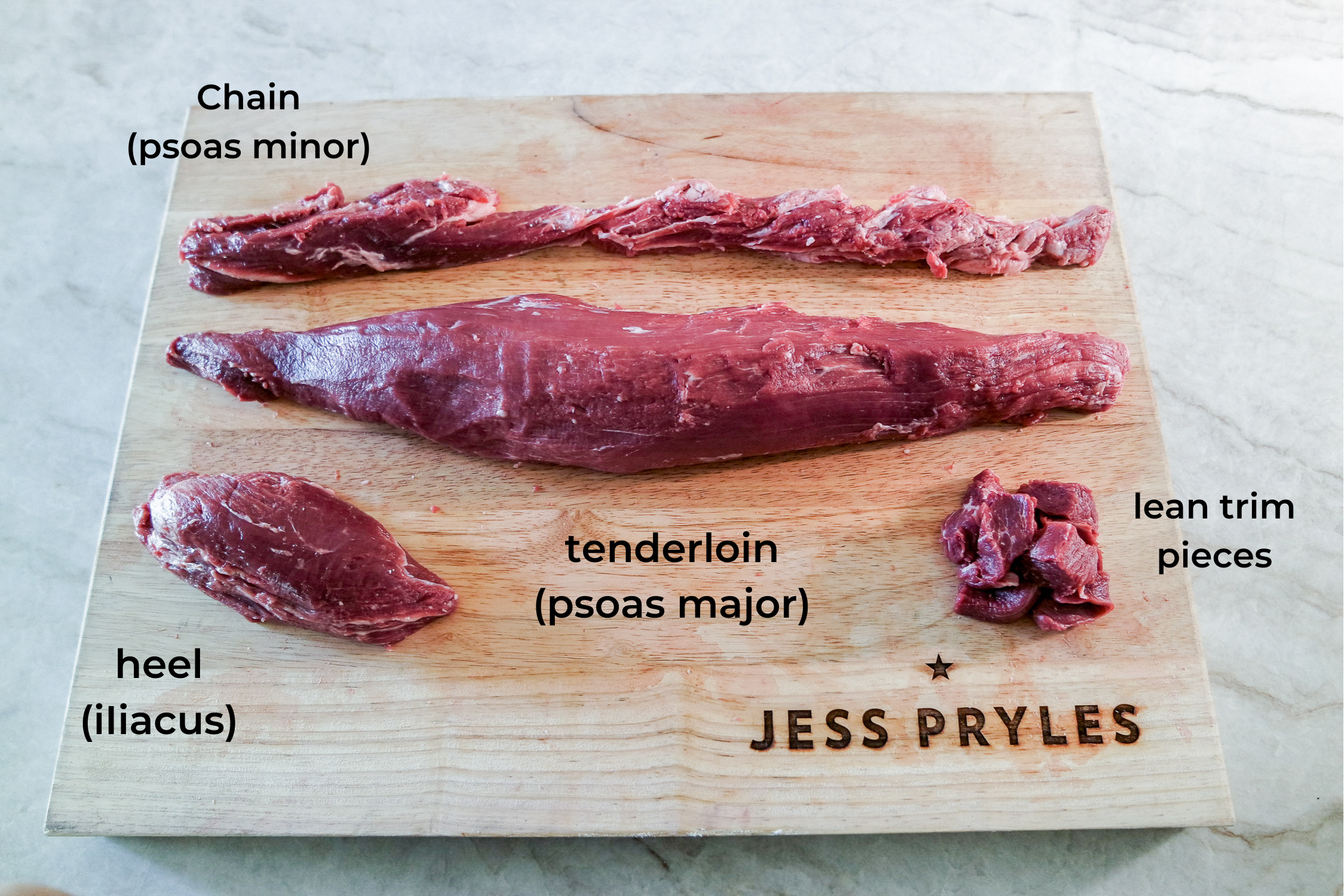

The DA tenderloin cut into 6 individual steaks (top of picture). The heal is seen on the bottom left with a little extra trim from chain at bottom right.

The heel or wing as noted in an earlier image, is actually a distinct muscle, the iliacis, and not a true tenderloin which is the psoas major. It is typically cut off whole as it can be used to make a delicious small roast. Alternatively it can be cut for stew, stir fry, or even beef carpacio if your knife skills are good and knife sharp.

Lovely 15 day DA filet mignon pan seared in butter and garlic.

Plated with toasted home made baguette and creamed spinach.

Topped with sautéd “gourmet” mushroom mix and home made demi-glace tableside.

I only wish you could have tasted the end result. It was of course extremely tender but with a slight dry age flavour not quite like any tenderloin I have eaten. In short, delicious! I will definitely being doing this again and may even go a little longer than 15 days to see if I can pull out even more flavour in what otherwise is a tender but lean and somewhat bland piece of meat.